Lasers are used in a variety of manufacturing processes, each with a different purpose. The three basic processes in which lasers are widely used in manufacturing are laser cutting, laser welding, and laser engraving/marketing.

laser cutting:

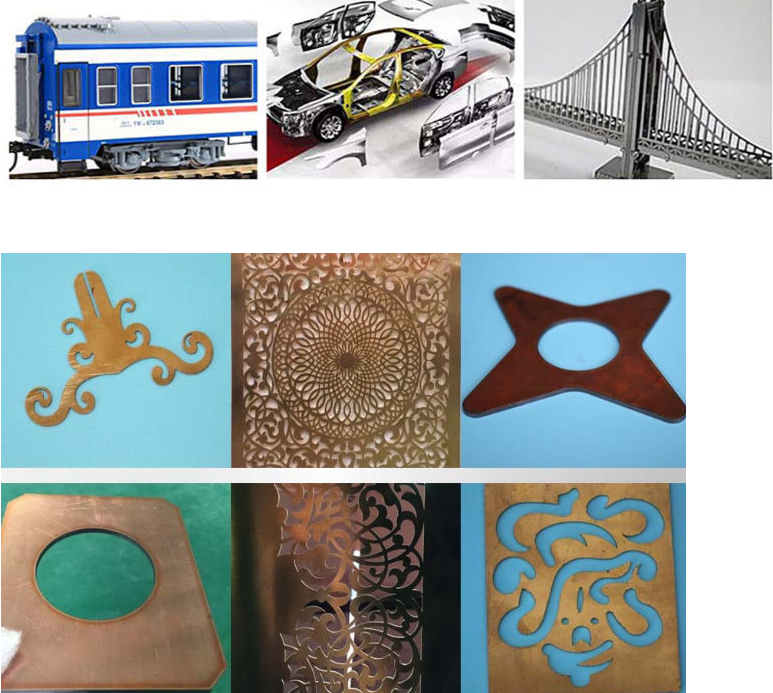

Laser cutting is a process that uses a laser beam to precisely cut materials such as metal, plastic, wood, and composites. The laser beam is focused and directed onto the surface of the material, causing it to melt, burn or vaporize. The intense heat generated by the laser results in clean and accurate cuts, allowing the production of complex shapes and fine details. The process is widely used in industries such as automotive, aerospace and electronics to manufacture parts with high precision and minimal material waste.

Laser welding:

Laser welding is a technology that uses a laser beam to join or fuse materials together. A high-energy laser beam generates heat that melts the material at the joint, then solidifies to form a strong bond. Laser welding has several advantages over traditional welding methods, including reduced heat-affected zones, minimal distortion, and the ability to weld thin and delicate materials. It is commonly used in industries such as automotive manufacturing, electronics, and medical device manufacturing, where welding accuracy and cleanliness are critical.

Laser engraving/marking:

Laser engraving and marking involves using a laser beam to change the surface of a material to create marks, patterns or designs. This process is typically used to add serial numbers, logos, barcodes, and other identifying information to products. Lasers selectively remove or modify material surfaces, leaving permanent high-contrast marks. Laser engraving and marking has applications in industries including jewelry, electronics, and packaging, providing a precise and efficient way to add branding or informational details to a variety of materials.

These three laser processes demonstrate the versatility and precision that lasers bring to manufacturing, helping to advance technology and produce high-quality products.