High-tech laser and polishing technology is an integral part of various industries, providing precise, efficient and advanced methods for material processing and finishing. Here are some key points and applications of these technologies:

laser technology

Laser cutting and engraving:

Precision: Laser cutting provides high precision for complex designs in materials such as metal, plastic, wood and glass.

Speed: Faster than traditional methods, lasers can quickly cut materials and increase production efficiency.

Versatility: Works with a variety of materials, making it a versatile tool in manufacturing, automotive, aerospace, art, and more.

Laser welding:

Strength: Produces strong, clean welds with minimal heat affected zone.

Purpose: For joining high-precision components in the automotive and aerospace industries.

Laser Marking:

Permanent Marking: Used to mark products with serial numbers, barcodes and logos.

Non-contact process: does not damage the integrity of the material.

Laser cleaning:

Environmentally Friendly: Removes pollutants, oxides and residues without the use of chemicals.

Usage: Used for mechanical repair, maintenance and preparation of welding surfaces.

Polishing technology

Mechanical polishing:

Abrasive technology: The use of abrasives to smooth surfaces, usually in multiple stages, from coarse to fine.

Usage: Used in manufacturing, automotive, jewelry and other industries to achieve high gloss.

Chemical Mechanical Polishing (CMP)

Precision: Combining chemical and mechanical processes to achieve surface smoothness on a microscopic level.

Usage: Widely used for planarization of silicon wafers in semiconductor manufacturing.

Electrolytic polishing:

Surface Smoothing: Uses an electrochemical process to remove material and smooth surfaces.

Hygiene: Produces highly corrosion-resistant and cleanliness surfaces suitable for medical and food processing equipment.

Ultrasonic polishing:

Micro-Grade Precision: Uses ultrasonic vibrations to polish complex and detailed parts.

Usage: Suitable for molds, molds and components requiring high precision and surface quality.

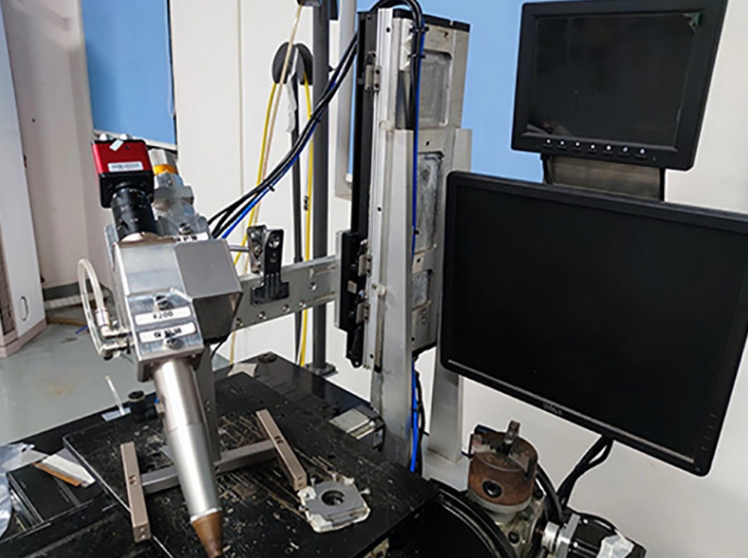

Integrated laser and polishing technology

Combining laser and polishing technologies to improve manufacturing capabilities:

Hybrid System: Machine that combines laser cutting/welding with polishing for seamless production.

Automation: Automated systems increase efficiency, consistency, and reduce manual labor.

Quality Control: Advanced monitoring systems ensure high quality finished products and precise specifications.