CNC fiber laser

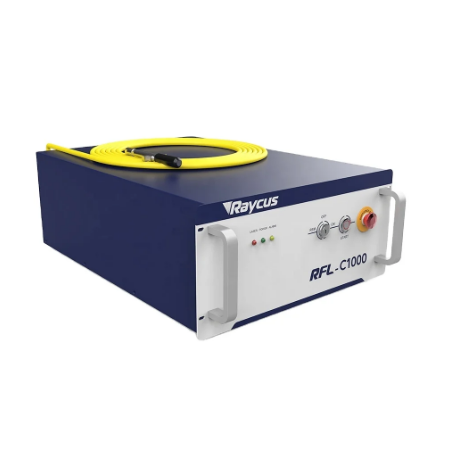

Laser welding cutting important working parts:

CNC fiber laser: High-power fiber laser heads usually use fiber lasers as laser sources. Fiber lasers are efficient, reliable, and stable, and are suitable for industrial applications that require high-power lasers.

High power output: This type of laser head is usually designed to output relatively large laser power to meet the requirements of deep cutting, high-speed welding or other high-power laser applications. Power levels may be in the kilowatt (kilowatt range) or above.

Beam quality: High-power fiber laser heads usually have good beam quality, which is crucial to maintaining the focusing performance of the laser during long-distance transmission.

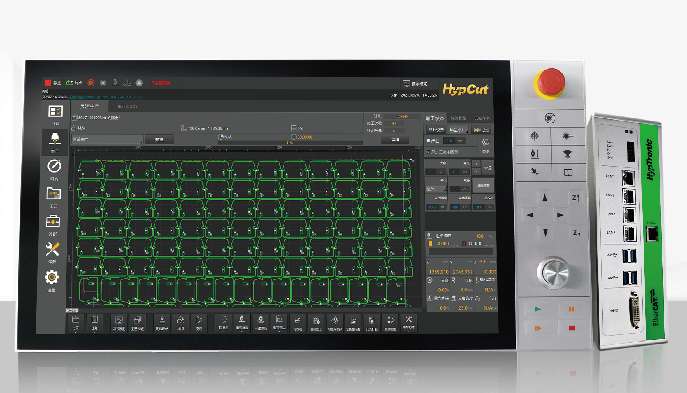

computer software

CNC laser welding and cutting machine is inseparable from the computer:

Computer software that improves the efficiency of fiber laser welding and cutting machines is key. Our advanced software optimizes the operating interface, enables precise cutting and welding, and improves production efficiency. Through intelligent algorithms, our software ensures high-performance operation of the equipment while reducing errors. Choosing our fiber laser machine means choosing advanced software technology to inject greater flexibility and creativity into your production process.

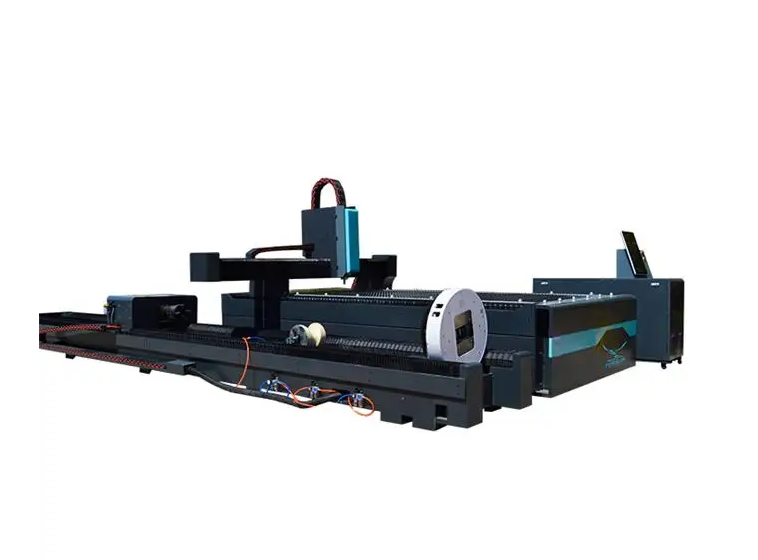

CNC fiber laser head

Industrial laser heads act on laser machines:

The industrial laser head is the core component of the laser machine and plays a key role in the laser machine. The following are the main functions of industrial laser heads in laser machines:

Beam focusing: The laser head focuses the laser beam to a very small point through the optical lens system to achieve a high energy density spot, thereby enabling precise cutting, welding or marking.

Optical path control: The laser head accurately controls the optical path of the laser through a combination of mirrors and lenses to ensure that the laser beam is accurately projected onto the work surface to achieve the required cutting or welding shape.

Auto-focus: The advanced laser head has an auto-focus function, which can automatically adjust the focus according to different working distances to ensure that the best focus position can be maintained during the entire working process.

Real-time monitoring: Some laser heads are equipped with sensors and monitoring systems that can monitor the temperature, humidity and other factors of the working environment in real time to ensure the stability and performance of the laser.

High-speed cutting and positioning: The industrial laser head is designed for high-speed cutting and positioning. Its precise beam control and fast response time enable efficient processing on industrial production lines.

Adaptable to different materials: Able to adapt to different types of materials, including metals, plastics, ceramics, etc., by adjusting laser parameters and optical configuration, precise processing of various materials can be achieved.

Overall, industrial laser heads play a vital role in laser machines, determining the accuracy, efficiency and flexibility of laser processing.

Industrial laser machine work field platform

User the laser table acts on the laser machine:

The laser machine workbench is a key component of the laser machine and plays an important role in laser processing. The following are the main functions and functions of the laser machine workbench:

Supporting the workpiece: The laser machine table provides a flat surface to support the workpiece to be processed. This ensures that the workpiece can be stably positioned and maintain the correct working posture during laser processing.

Motion control: The workbench usually has adjustable height and position to achieve precise positioning and motion control of the workpiece. This allows the laser beam to be accurately focused on designated areas of the workpiece for cutting, welding or marking.

Automatic positioning: Advanced laser machine workbenches usually have automatic positioning functions, which can realize intelligent perception and adjustment of the workpiece position through the CNC system to adapt to different production needs.

Adsorbing or fixing workpieces: Some workbenches are designed to fix workpieces through vacuum adsorption or clamping mechanisms during laser processing to ensure that the workpieces do not move or shake during high-speed laser processing.

Improve production efficiency: Through intelligent control of the workbench, functions such as automatic workpiece change and continuous processing can be realized, improving production efficiency and reducing the need for manual intervention.

Adapt to different materials: The workbench design should be able to adapt to different types and sizes of materials to ensure that a diverse range of workpieces can be processed on the same laser machine.

Generally speaking, the laser machine workbench plays a key role in support, positioning and motion control in the laser processing system, and has an important impact on the accuracy and efficiency of laser processing.