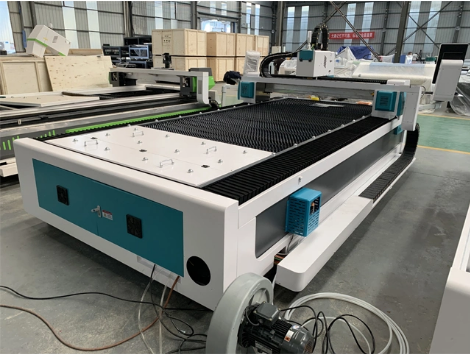

A CNC (Computer Numerical Control) fiber laser cutting machine is a sophisticated tool used for precision cutting of various materials, primarily metals. The machine utilizes a high-powered fiber laser to cut through the material with great accuracy. The main components of a CNC fiber laser cutting machine include:

- Laser Source:

- Fiber lasers are commonly used for their high efficiency and reliability.

- The laser source generates the laser beam used for cutting. It typically includes a laser resonator, pump diodes, and fiber optic cables.

- Controller:

- The CNC controller is the brain of the machine. It interprets the CNC code (G-code) and converts it into electrical signals that control the movement of the machine components.

- The controller also manages the laser power, gas flow, and other parameters during the cutting process.

- Machine Bed:

- The machine bed provides a stable platform for the workpiece and the cutting components. It is usually made of a rigid material like steel to ensure accuracy and stability.

- Cutting Head:

- The cutting head contains the focusing lens and nozzle through which the laser beam is delivered to the workpiece.

- Some cutting heads are equipped with automatic height control (AHC) systems to maintain a constant distance between the cutting head and the workpiece for consistent cutting.

- X, Y, Z Axes:

- These are the three axes of movement for the cutting machine:

- X-axis: Horizontal movement along the length of the machine.

- Y-axis: Horizontal movement perpendicular to the X-axis.

- Z-axis: Vertical movement, controlling the distance between the cutting head and the workpiece.

- These are the three axes of movement for the cutting machine:

- Worktable:

- The worktable is where the material being cut is placed. It can be fixed or equipped with a CNC-controlled movement system for repositioning during cutting.

- Drive System:

- The drive system includes motors and control systems that move the X, Y, and Z axes in response to commands from the CNC controller.

- Cooling System:

- The laser source generates heat during operation, and a cooling system is used to maintain optimal operating temperatures and prevent overheating.

- Gas Supply System:

- Assist gases, such as oxygen or nitrogen, are often used to enhance the cutting process. They help to blow away molten material and improve the quality of the cut.

- Dust and Fume Extraction System:

- A system for removing dust, smoke, and fumes produced during the cutting process, ensuring a safe working environment.

- Control Panel:

- A user interface where operators can input cutting parameters, monitor the machine’s status, and control various aspects of the cutting process.

These components work together to enable precise and efficient laser cutting in various industrial applications. Keep in mind that specific features and components may vary depending on the manufacturer and model of the CNC fiber laser cutting machine.