Choosing the right laser cutter to cut metals of varying thicknesses requires consideration of several factors, including the type and thickness of the metal, required cutting speed and accuracy requirements. Here are some key considerations:

Laser power:

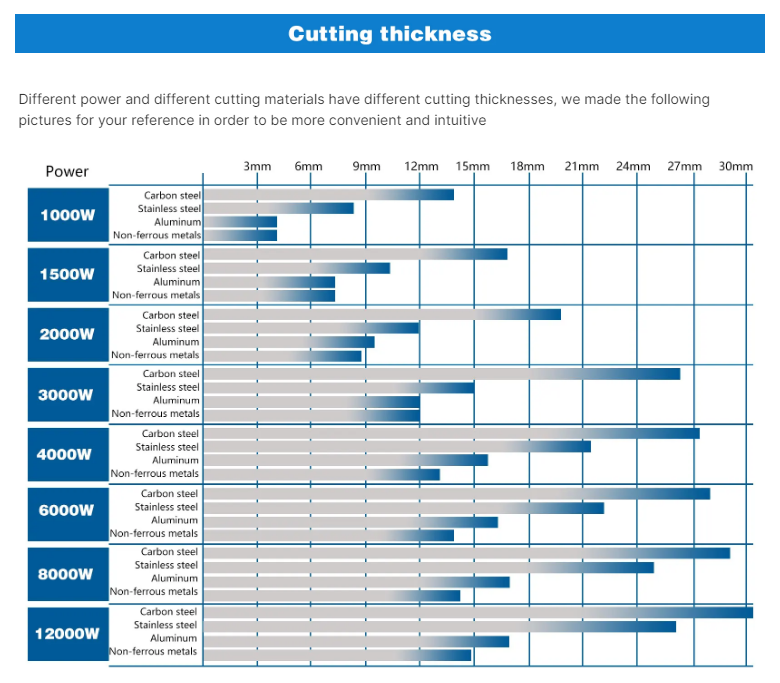

Low-power lasers (up to 1 kilowatt) are suitable for thin metals, such as stainless steel and aluminum, about 1/8 inch (3 mm) thick.

Medium power lasers (1kw to 3kw) can handle thicker materials ranging from 1/8 inch (3mm) to 1/2 inch (12mm).

High-power lasers (more than 3 kilowatts) are capable of cutting materials thicker than 1/2 inch (12 mm).

material type:

Different laser cutting machines are optimized for specific materials. For example, CO2 lasers are often used on organic materials such as wood and acrylic, while fiber lasers are more effective on metals.

Fiber optic and CO2 lasers:

Fiber lasers are often the first choice for metal cutting due to their high efficiency and better beam quality compared to CO2 lasers. Suitable for high-precision cutting of various metal thicknesses.

Cutting speed:

Higher laser power generally allows for faster cutting speeds. Consider your production requirements and choose a machine that can meet your expected throughput.

Auxiliary gas:

The type of assist gas used during cutting affects the quality and speed of the process. Common gases include oxygen (for steel) and nitrogen (for stainless steel and aluminum). Some machines may support different gases for best results.

Table size and configuration:

Make sure your laser cutter has a large enough table size to accommodate the size of the sheet metal you plan to use. In addition, check whether the machine has functions such as a shuttle table for continuous production.

Automation and CNC control:

Machines with advanced CNC (computer numerical control) systems and automation capabilities can increase efficiency and precision. Look for features like autofocus, automatic nozzle replacement, and advanced nesting software.

Maintenance and service:

Consider ease of maintenance and the availability of service and support from the manufacturer. Downtime can be expensive, so choose a machine with a good reputation for reliability.

Budget:

Laser cutters vary in price, so it’s important to balance your needs with your budget. Consider long-term benefits and return on investment when making decisions.

Before purchasing, it is recommended to consult with a laser cutting machine supplier or manufacturer to discuss your specific needs and obtain recommendations based on your application and production requirements.