Laser power management involves the control and optimization of the power output from lasers for various applications. It is crucial in maintaining the stability, efficiency, and safety of laser systems.

Power Control:

Output Power Adjustment: Many laser systems allow adjustment of output power. This can be manual or automatic, depending on the application.

Closed-loop control: Some systems use feedback mechanisms to maintain constant output power. This includes monitoring power output and adjusting in real time to compensate for fluctuations.

Beam quality:

M-mode and q-switching: Modulating the laser output through techniques such as m-mode and q-switching helps control the duration and intensity of the laser pulse, thereby affecting beam quality.

Beam Collimation: Proper collimation ensures that the laser beam maintains a consistent diameter and divergence, contributing to better beam quality.

cooling system:

Thermal Management: High-power lasers generate heat and an effective cooling system is essential to prevent overheating. This may involve active cooling methods such as liquid cooling or air cooling.

Temperature Monitoring: Monitoring the temperature of laser components helps maintain optimal operating conditions.

Safety measures:

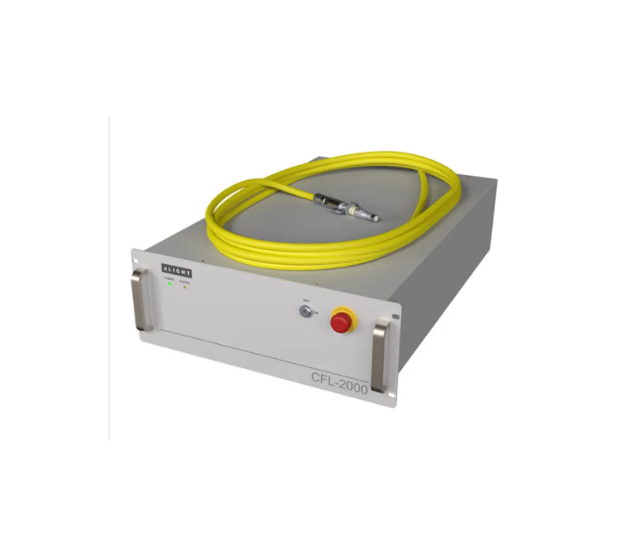

Interlocking system: Laser systems often have an interlocking mechanism that automatically shuts down the laser if certain safety conditions are not met.

Emergency shutdown: A fast and effective emergency shutdown mechanism is essential to prevent accidents and ensure user safety.

electricity supply:

Stable power supply: Lasers require a stable power supply to maintain consistent output. Uninterrupted power supply UPS (Uninterrupted power supply) can prevent interruptions when power fluctuates.

Beam delivery system:

Optical components: Proper selection and maintenance of optical components (mirrors, lenses, etc.) in a beam delivery system are critical to efficiently transmitting power.

Beam expanders: In some applications, beam expanders can be used to control laser spot size and power density.

Calibration and Monitoring:

Power meter: Calibrate the power meter regularly to ensure accurate measurement of laser output power.

Monitoring system: Continuous monitoring of key parameters helps detect anomalies and allows timely maintenance or adjustments.

diagnosis:

Fault Detection: Laser systems may contain diagnostic tools to identify and resolve faults or issues that affect power output.

Remote monitoring: Some laser systems allow for remote monitoring, allowing operators to check performance and make adjustments from a distance.

Effective laser power management is essential in various industries, including manufacturing, medical applications, research and telecommunications, to ensure reliable and safe operation of laser systems.